Galex X720 Blower: Empowering World-Leading PCB Production Lines with Efficient, Energy-Saving, and Interference-Free Operation

Successfully replaces side channel blowers, eliminating high-frequency interference and noise issues, enhancing efficiency for one of China's Top 2 PCB manufacturers.

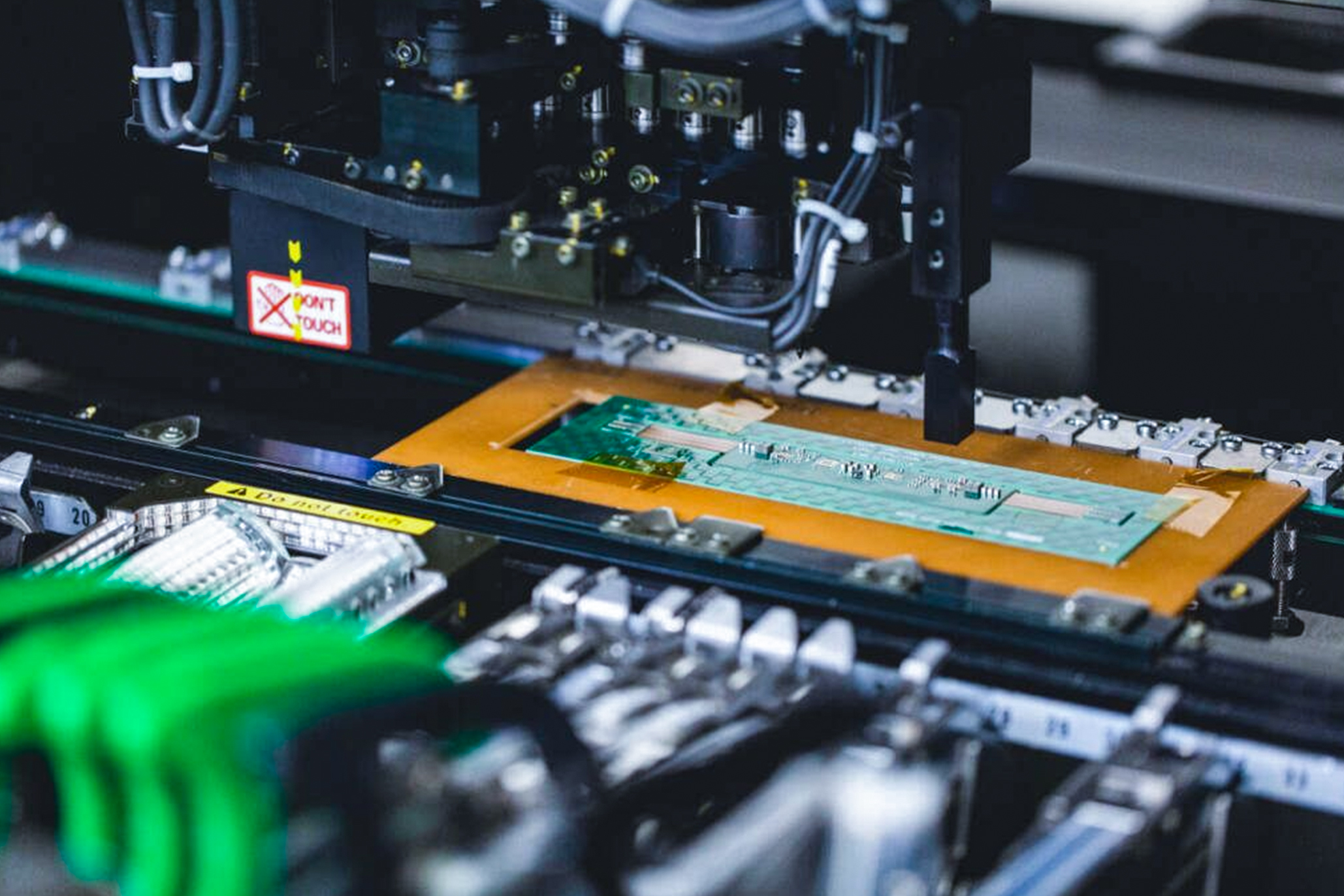

In the realm of global precision electronics manufacturing, every stage of PCB (Printed Circuit Board) production demands exceptional stability and efficiency. The drying stage is a critical step in PCB horizontal production lines, where blower performance directly impacts production yield, energy consumption, and the work environment. Leveraging its advanced blower technology, Galex's flagship X720 High-Pressure Blower has been successfully deployed in the drying stage of a globally renowned PCB horizontal production line, serving one of China's top two PCB manufacturers. Its outstanding performance has earned deep recognition from the customer.

Addressing Challenges with Proven Performance

The side channel blowers previously used on the production line struggled to meet escalating efficiency, energy consumption, and operational stability demands. The customer urgently needed a high-performance blower capable of delivering powerful, stable drying force while significantly reducing energy consumption, eliminating motor-induced high-frequency interference affecting sensitive instruments, and mitigating workshop noise. The Galex X720 High-Pressure Blower was selected and successfully implemented based on its superior design and technological advantages.

Operating within the demanding production environment, the X720 demonstrated impressive performance metrics:

Pressure: 22.5 kPa (providing strong, focused drying force)

Flow Rate: 12.5 m³/min (meeting high-speed production line requirements)

Operating Power: Only 7.8 kW (demonstrating significant energy efficiency)

Operating Environment: Ambient Pressure 99.5 kPa, Ambient Temperature 28°C (stable adaptation to site conditions)

Core Value: Beyond Energy Savings – Stability and Quiet Operation

The deployment of the Galex X720 blower delivered multiple significant benefits to this PCB industry leader:

High Efficiency & Energy Savings, Significant Cost Reduction: Compared to the original side channel blowers, the X720 delivers the required pressure and flow at only 7.8 kW, drastically reducing energy consumption. This translates to substantial operational cost savings for the customer, showcasing Galex's core advantage in energy efficiency and environmental protection.

Complete Elimination of High-Frequency Interference: High-frequency harmonic interference generated by motors in high-speed blowers has long been an industry pain point, often disrupting sensitive precision measurement instruments on production lines. The X720 incorporates specialized EMC design and optimized motor drive technology, ensuring zero impact on production line instruments during operation. This guarantees the accuracy of production data and the stability of process control, significantly enhancing line reliability.

Significant Noise Reduction, Improved Environment: The X720 features deep optimization in aerodynamic design and structural noise reduction. Its operating noise is significantly lower than the original blowers. This creates a more comfortable and quieter working environment for operators and aligns with modern factories' pursuit of green, low-noise production.

Stable & Reliable, Production Guaranteed: Consistent performance in key parameters like pressure and flow ensures reliable operation under continuous, high-intensity production demands. This guarantees uniformity in the PCB horizontal line drying process and final product quality.

Successful Replacement, Setting an Industry Benchmark

The successful application of the Galex X720 High-Pressure Blower in this globally renowned production line at one of China's top two PCB manufacturers is more than just a product upgrade. It is powerful validation of Galex's technological strength in solving core industry challenges. It effectively replaced the traditional side channel blower solution, delivering equivalent or superior process results while achieving comprehensive value enhancement through energy efficiency, interference-free operation, and an improved environment.

Choose Galex for Efficiency, Stability, and Quiet Operation

The Galex X720 series of High-Pressure Blowers continues to provide leading fluid solutions for global high-end manufacturing. Whether for demanding PCB processes or other industrial scenarios requiring efficient, clean, low-noise, interference-free power sources, Galex is committed to being your trusted partner.

Discover how the Galex X720 can revolutionize your production line:/contact_us.html